Linear Actuator

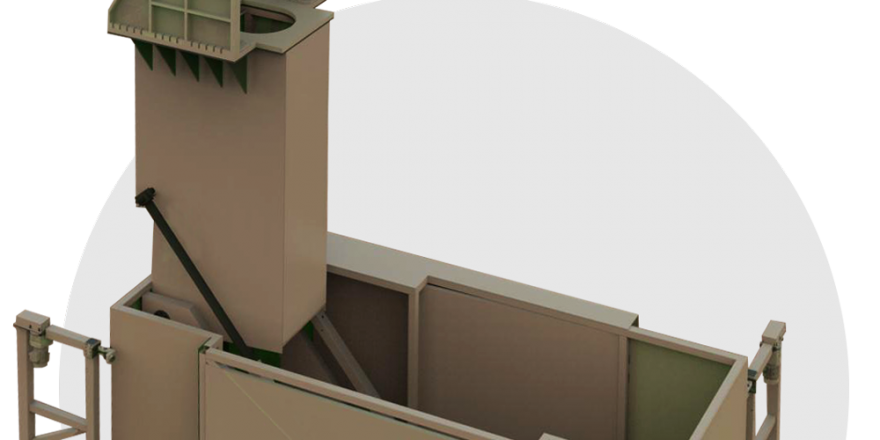

Linear actuators, as compact components that use electricity to provide linear motion, are often required for both civil and military applications. The first application of the innovative linear actuators developed by GES Engineering is the Automatic Weapon Cocking System that serves as a mechanism to move the arm of the weapon. The system meets an important need in the military field.

Why?

GES Engineering's innovative linear actuators combine an efficient and reliable electromechanical structure with software functions and interfaces that offer ease of use. The first application of these actuators has been in the Automatic Weapon Cocking System.

Operating in compliance with all military environmental and electrical standards, the Automatic Weapon Cocking System has been developed for use in the remote-controlled weapon systems of military vehicles. The system allows the weapons located outside the vehicle to be cocked automatically, quickly and safely from within the vehicle. In this way, in mission scenarios involving external threats, the need to interfere with the weapon by going outside or on the vehicle is eliminated. The system automatically detects the weapon type, while the installed easy-to-use software prevents operator error, allowing flawless weapon cocking every time.

Innovative Features

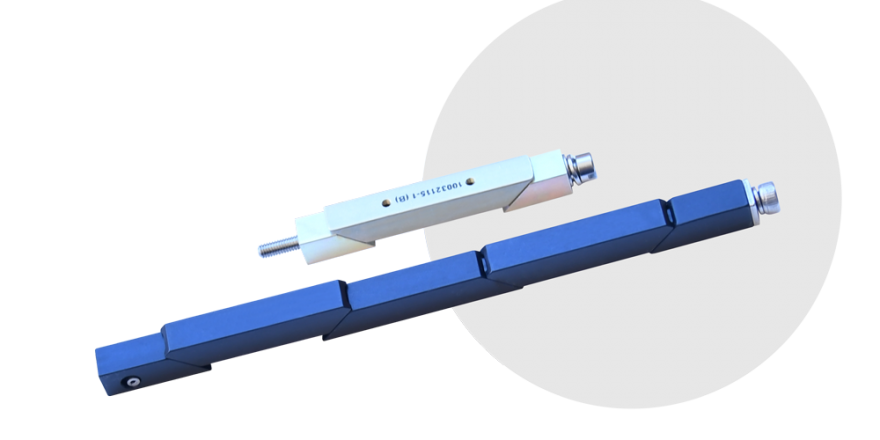

The innovative features offered by GES Engineering’s linear actuators are as follows:

- High-strength body structure

- Improved internal bearing

- Smooth movement, without the need for additional bearings

- User friendly interface

- Automatic weapon recognition system

- Automatic speed and power adjustment, depending on the weapon

- Incorrect weapon selection warning and high current warning

- Variable speed throughout the cocking

- Smart design that remembers its last position and prevents unsafe situations even in the event of a power failure

- Long-lasting mechanical structure that requires no maintenance

- RS422 and CANopen communication protocols

Applicability

The connection interfaces of GES Engineering's linear actuators can easily be adapted to their respective positions on the vehicle. In addition, to enable easy maintenance, the mechanical brackets allow rapid mounting or dismounting. The speed, strength, thrust and body structure can be customised according to customer needs, and alternative products can be introduced quickly.

Related Developments

In the military land vehicles sector, there is a need for linear actuators that can detect what weapons are mounted on remote-controlled weapon systems, and automatically adjust themselves accordingly. With its existing features as well as those to be added in the future, the Automatic Weapon Cocking System designed by GES Engineering is expected to become a preferred product among weapon system producers and land vehicle manufacturers.

Potential Projects and Areas of Use

GES Engineering’s Linear Actuators:

- can be used in all military applications requiring compact and smart solutions that provide strong and fast linear motion,

- can be used in all military vehicles as a Weapon Cocking Mechanism;

- can be used to open and close hatches or doors in outdoor and indoor environments;

- can be used to meet alternative needs such as the levelling or moving of various mobile platforms.

Specifications

- Automatic detection of weapon type when used as an Automatic Weapon Cocking System

- Detection of incorrect weapon selection when used as an Automatic Weapon Cocking System

- Ability to remember its last position in the event of a power failure

- Jam and strain detection

- Variable speed control

- Ability to host advanced bearing elements and solutions

- Architecture that can be integrated into a variety of gun turrets

- Push/pull capacity: 100 kg

- Load holding capacity without system power: 150 kg

- Location sensing distance: 1 mm

- Communication interface: RS422 and CANopen

- Movement speed: 100 mm/sec

- Compatibility: MIL-STD-810, IP67, MIL-STD-461F, CE102 and RE102